Precision Machining

Precision Machining Services

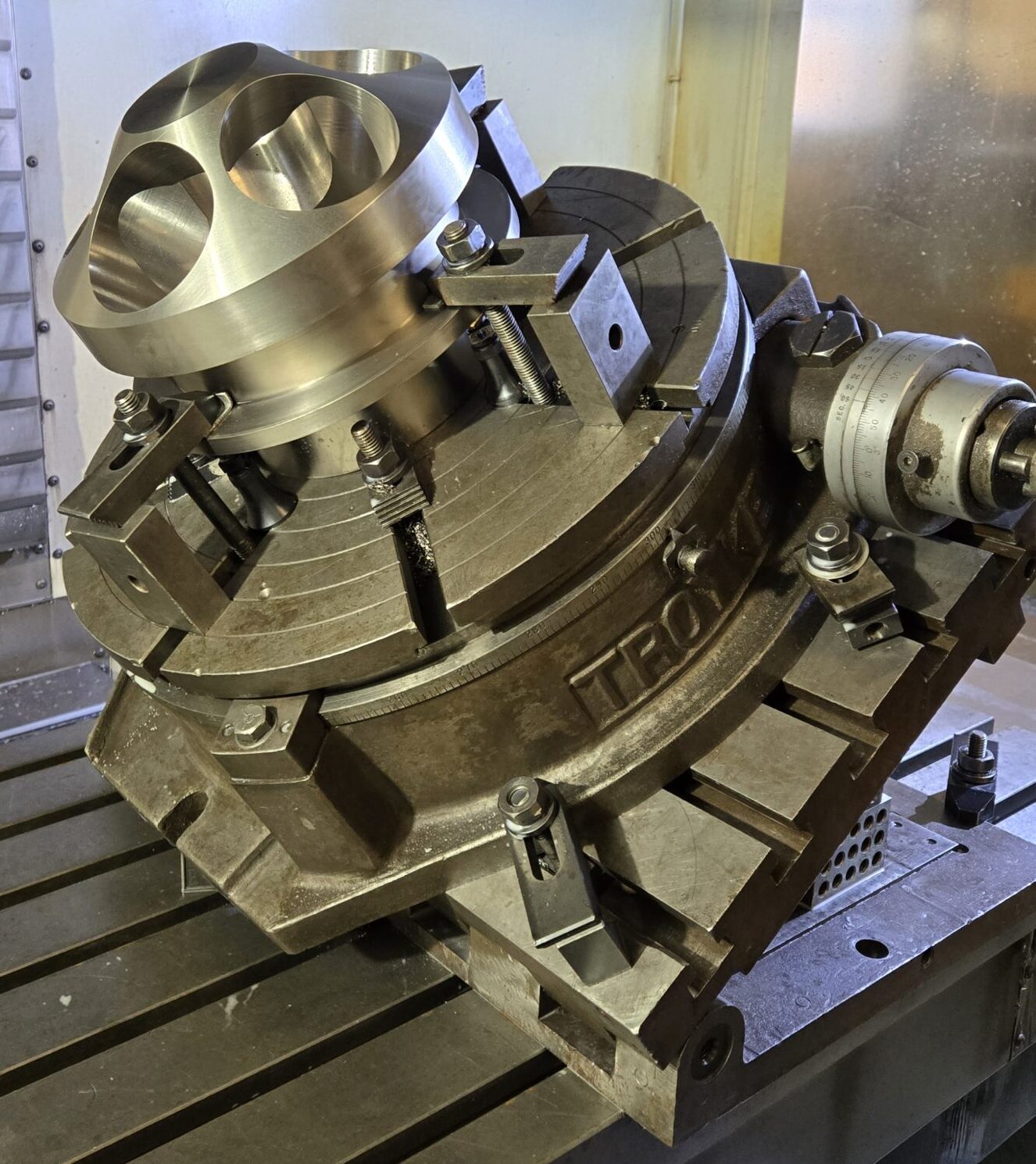

Precision machining is critical in modern manufacturing, engineering, and technology development. It ensures high accuracy, tight tolerances, and exceptional quality in producing parts and components. Precision machining allows manufacturers to create components with extremely tight tolerances and allows for the production of custom parts tailored to specific needs. This is vital for research, prototyping, and specialized manufacturing where standard parts are not suitable. Bain Machine specializes in delivering precision machining services such as CNC milling, CNC turning, and manual machining. Our commitment to quality and precision ensures that every part we produce meets the strictest tolerances and specifications, providing our clients with reliable and efficient solutions.

CNC Milling: Advanced CNC Milling for High-Precision Part Production

Precision CNC (Computer Numerical Control) milling is a manufacturing process that uses computerized controls and rotating multi-point cutting tools to remove material from a workpiece. It is a key technique in precision machining, enabling the production of highly accurate and complex parts for various industries. Bain Machine utilizes advanced CNC milling machines to produce intricate, high-quality parts with extreme accuracy and efficiency.

Advantages of Precision CNC Milling

- High Accuracy & Repeatability

- Complex Geometries

- Efficient & Cost-Effective

- Wide Range of Materials

- Versatility

Materials

- Aluminum (6061, 7075)

- Stainless steel (304, 316, 17-4)

- Alloy Steel (4140, 4340, 1018)

- Titanium (Grade 5, Grade 7)

- Tool steel (O-1, A-2, D-2)

- Hastelloy C276

- Bronze

- Brass

Applications

From prototyping to full-scale production runs, our CNC milling services are suitable for creating components like housings, brackets, and enclosures that require precise dimensions and smooth finishes.

CNC Turning: CNC Turning Services for Creating Cylindrical Components

Precision CNC turning is a machining process that uses computer-controlled lathes to remove material from a rotating workpiece. It is widely used for producing cylindrical, conical, and round parts with high accuracy and repeatability. Bain Machine utilizes advanced CNC turning for manufacturing high-quality, high-precision parts that require smooth finishes and tight tolerances. It is a fast, efficient, and scalable method, making it a go-to solution for industries demanding precision and reliability.

Advantages of Precision CNC Turning

- High Accuracy & Consistency

- Fast & Efficient Production

- Ideal for Cylindrical & Rotational Parts

- Compatible with a Wide Range of Materials

- Versatility with Multi-Axis Lathes

Materials

- Aluminum (6061, 7075)

- Stainless steel (304, 316, 17-4)

- Alloy Steel (4140, 4340, 1018)

- Titanium (Grade 5, Grade 7)

- Tool steel (O-1, A-2, D-2)

- Hastelloy C276

- Bronze

- Brass

Applications

CNC turning is particularly suited for producing components such as shafts, pins, housings, couplings, fasteners, adapters, and axles.

Precision Manual Machining: Machining for R&D, One-Off Parts, and Low-Run Quantities

Precision manual machining refers to the process of shaping, cutting, and finishing metal or other materials using manually operated tools and machines such as lathes, mills, drills, and grinders. Unlike CNC machining, which is computer-controlled, manual machining relies on the skill and expertise of the machinist to achieve high precision and accuracy. Bain Machine maintains manual machines for custom manufacturing and quick turn around.

Advantages of Precisions Manual Machining

- Hands-On Control & Flexibility

- No Need for CNC Programming

- Cost-Effective for Small Batches

- Essential for Fine-Tuning & Repairs

Materials

- Aluminum (6061, 7075)

- Stainless steel (304, 316, 17-4)

- Alloy Steel (4140, 4340, 1018)

- Titanium (Grade 5, Grade 7)

- Tool steel (O-1, A-2, D-2)

- Hastelloy C276

- Bronze

- Brass

Applications

Conventional machining is particularly useful for quick turnaround on small projects, creating custom parts for specialized equipment, modifying existing components.

Industries Served

At Bain Machine, we serve a diverse range of industries, ensuring we meet the unique challenges and standards of each sector. Our focus on precision and quality makes us a trusted partner for:

Automation:

Components for automated systems and robotics.

Aerospace:

High-precision parts for stringent aerospace requirements.

Defense:

Critical components for defense systems.

Construction:

Durable parts for machinery and infrastructure.

Steel Mills:

Specialized components for extreme conditions.

Automotive:

Precision parts that enhance vehicle performance.

Chemical:

Components designed for demanding environments.

Our expertise allows us to deliver tailored solutions that exceed performance expectations across various fields.

Why Choose Bain Machine?

At Bain Machine, our dedication to excellence drives us to continually enhance our capabilities in precision machining. We invest in state-of-the-art equipment and employ skilled machinists who are experts in their field. Our focus on quality control ensures that every part we produce meets or exceeds industry standards.

We understand the critical role that precision machining plays in the success of our clients' projects. By choosing Bain Machine as your manufacturing partner, you gain access to a wealth of expertise and resources dedicated to delivering superior results. Whether you need a single prototype or large-scale production runs, we are committed to providing solutions that drive your success.

Contact Us

We’d love to hear from you! Whether you have questions about our services, want to discuss

a project, or need a quote, our team is here to assist you.

Feel free to reach out via phone or email or visit us at our facility. We look forward to partnering with you on your next precision machining project!