Bain Machine is a precision

machine shop

At Bain Machine, we pride ourselves on making your life a little easier by providing a fast quote, great communication, and high-quality parts shipped in a timely fashion.

About Us Request Quote

Our Process

Send us a CAD file

Upload your CAD files and supporting documents to our secure Smart RFQ form

Automatic DFM Analysis

Part geometry is analyzed for manufacturability and a digital quote is sent to you within 24 hours

Manufacturing Begins

Once the quote has been approved manufacturing begins on one of our multi-axis workcenters

Finishing Processes

Parts that require finishing are processed in house or via one of our trusted industry partners

Parts Shipped

Our shipping department then ensures secure packaging and rapid delivery of your order.

About Us

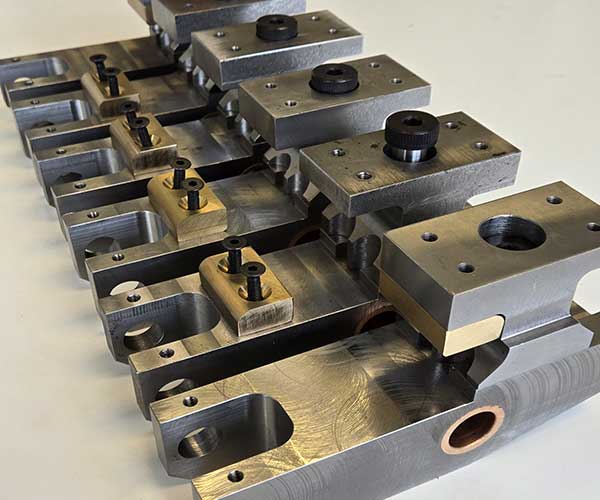

Bain Machine, located in Greater Cleveland, OH, is a machine shop dedicated to maintaining the highest standards in quality and service. For almost 40 years Bain has provided CNC machining, manual machining, welding, cutting, and assembly services. We specialize in small batch manufacturing ranging from 10 to 500 parts and custom manufacturing or prototyping ranging from 1 to 10 parts. Our number one goal is to provide a quality product, in a timely fashion that meets or exceeds expectations.

Services Offered

Bain Machine provides CNC machining, manual machining, welding, cutting, and assembly services. We specialize in small batch manufacturing ranging from 10 to 500 parts and custom manufacturing or prototyping ranging from 1 to 10 parts. Our proven ability to machine complex parts and weldments in a diverse group of materials has created decades long partnerships with our customers.

Machining

CNC Milling: CNC mills perform operations such as drilling, slotting, and contouring.

CNC Turning: CNC lathes perform operations such as facing, threading, and boring.

Manual Machining: Manual machines are used prototyping and small batch manufacturing ranging from 1 - 10 parts.

Assembly

Assembly services ranging from 2-15 parts along with bushings, bearings, and fasteners.

Prototyping

Prototyping services to test and refine designs before full production, ensuring alignment with customer needs.

This comprehensive suite of services positions Bain Machine as a one-stop solution for all your manufacturing needs, from concept to completion.

Our Mission & Commitment

Our mission is to provide quality products in a timely fashion. Our commitment to transparency and reliability fosters loyalty among employees, customers, suppliers and community. We do this by pursuing simple solutions for complex, technical challenges which allow innovative ideas and process improvements to be realized quickly and cost effectively.

Call Us Now (216) 518-0333

Why Choose Bain Machine?

At Bain Machine, our dedication to excellence drives us to continually enhance our capabilities in precision machining. We invest in state-of-the-art equipment and employ skilled machinists who are experts in their field. Our focus on quality control ensures that every part we produce meets or exceeds industry standards.

We understand the critical role that precision machining plays in the success of our clients' projects. By choosing Bain Machine as your manufacturing partner, you gain access to a wealth of expertise and resources dedicated to delivering superior results. Whether you need a single prototype or large-scale production runs, we are committed to providing solutions that drive your success.

Industries Served

At Bain Machine, our expertise spans across a diverse range of industries, allowing us to meet the unique challenges and exacting standards of each sector. Our commitment to precision, quality, and innovation makes us a trusted partner for businesses across various fields. We take pride in our ability to adapt our services to the specific needs of each industry, ensuring that we deliver components and solutions that meet or exceed the highest standards of performance and reliability.

Motorsports

Specialized in rapid one-off prototyping for quick turnaround without compromising quality. Expertise in 3-axis and 5-axis machining to meet the dynamic and time sensitive demands of the motorsports industry.

Aerospace

Precision machining for light weight parts with complex geometries used in the aerospace industry. Thorough CMM inspection and reporting procedures are implemented to guarantee components not only meet but surpass stringent standards. We provide complete material and hardware traceability documentation.

Defense

Our scope of work for the defense industry includes complex parts and sub-assemblies for autonomous aerial systems, combat robotics, and light tactical squad vehicles. We provide complete material and hardware traceability documentation.

Robotics

We provide rapid delivery of machined components for the robotics and industrial automation industries. Utilizing our 24/7 lights out production capabilities we can ensure rapid scalability without sacrificing quality.

Our Industry Expertise:

Automation:

Cutting-edge components for automated systems and robotics, driving efficiency and precision in manufacturing processes.

Aerospace:

High-precision parts that meet the stringent requirements of aerospace applications, ensuring safety and performance in flight.

Defense:

Critical components for defense systems, manufactured with the utmost attention to detail and security protocols.

Construction:

Durable parts for construction machinery and infrastructure projects, built to withstand demanding environments and heavy use.

Steel Mills:

Specialized components for steel production, engineered to endure extreme temperatures and harsh conditions.

Automotive:

Precision parts for automotive manufacturing, contributing to the performance, safety, and efficiency of modern vehicles.

Chemical:

Components tailored to meet the demanding and corrosive environments of the chemical industry, ensuring longevity and reliability.

This comprehensive list highlights Bain Machine's capabilities in providing a full range of machining and assembly services across various industries. Our versatility and expertise ensure that we deliver high-quality, efficient solutions for every project, regardless of its complexity or the industry it serves. By continually adapting to new technologies and industry standards, we remain at the forefront of manufacturing excellence, ready to meet the evolving needs of our diverse clientele.